Supplier Indoor Home And Commercial Use Waterproof Fireproof Luxury PVC Vinyl 4mm 5mm 6mm SPC Flooring

How Is SPC Flooring Made?

Mixing

To begin, a raw material mixture is placed in a mixing machine.

Once inside, the raw materials are heated to 125 - 130 degrees Celsius to remove any water vapor present.

Once finished, the material is cooled inside the mixing machine to prevent early

plasticization or processing auxiliary decomposition.

Extrusion

After leaving the mixing machine, the raw material goes through an extrusion process.

Temperature control is critical in this case to ensure that the material plasticizes properly.

The material is routed through five distinct zones.

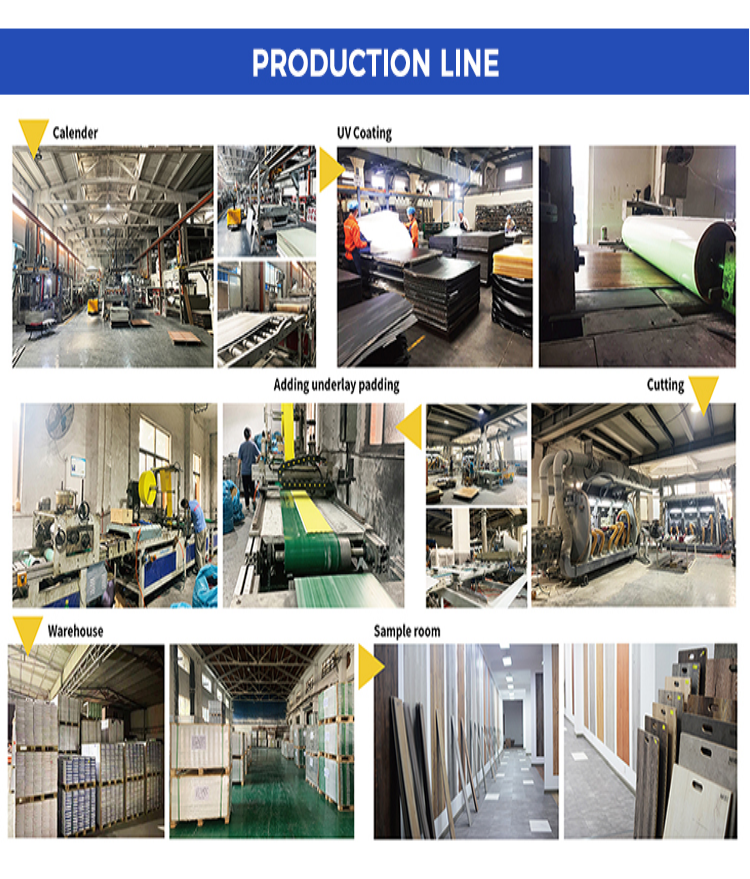

Calendaring

Once the material has been fully plasticized into a mold, it is time to begin the calendering process.

A series of heated rollers is used to compound the mold into a continuous sheet in this case. The width and thickness of the sheet can be precisely controlled and consistent by manipulating the rolls.

Once the desired thickness has been achieved, it is embossed using heat and pressure.

Engraved rollers are used to apply the textured design to the product's face, which can be a light "tick" or a "deep" emboss.

After the texture is applied, the scratch and scuff Top Coat is applied and the drawer is closed.

Drawer

The drawing machine, when used with frequency control, is directly connected to a motor that is perfectly matched to the production line speed and is used to deliver material to the cutter.

Cutter

The material is crosscut here to meet the appropriate guideline standard.

To ensure clean and equal cuts, a sensitive and accurate photoelectric switch signals the cutter.

Plate-Lifting Machine on Autopilot

Following the cutting of the material, the automatic plate-lifting machine will lift and stack the finished product into the packing area for pick-up.

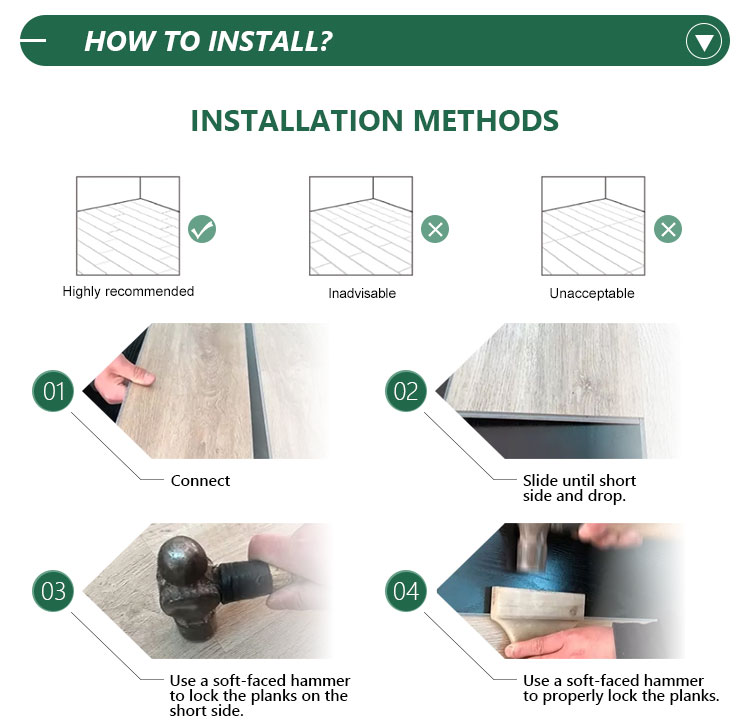

How Do You Put Down SPC Flooring?

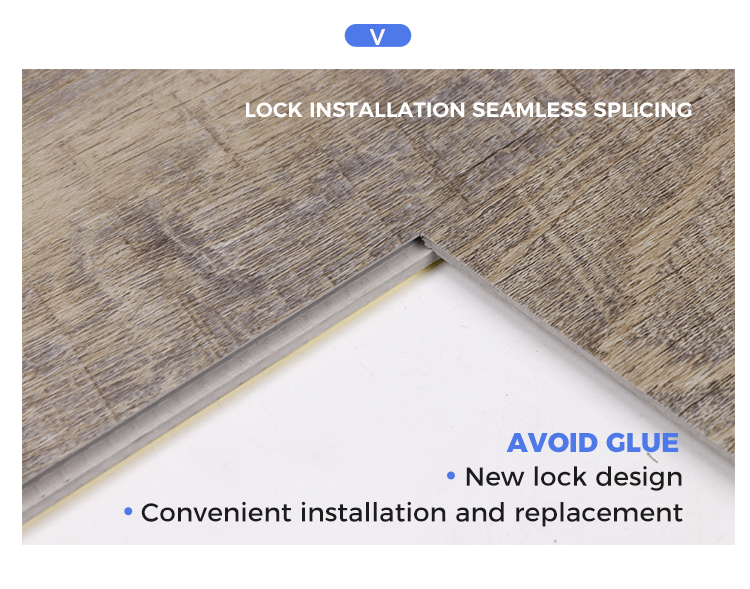

SPC luxury vinyl flooring is available in planks or tiles that snap together to form a floating floor.

Unlike previous versions, most do not require glue.

They're simple to put together, even easier than laminate planks, because they can be cut by scoring with a knife and snapping.

A saw is only required for cutting curves and notches.

SPC flooring can be installed over a variety of other flooring materials, including hardwood, vinyl, and some types of tile.

However, the sub-floor must be flat, so some preparation may be required first.

If the product you are installing does not have one, an underlayment is also recommended.

Finally, baseboards must be installed to keep the flooring in place.

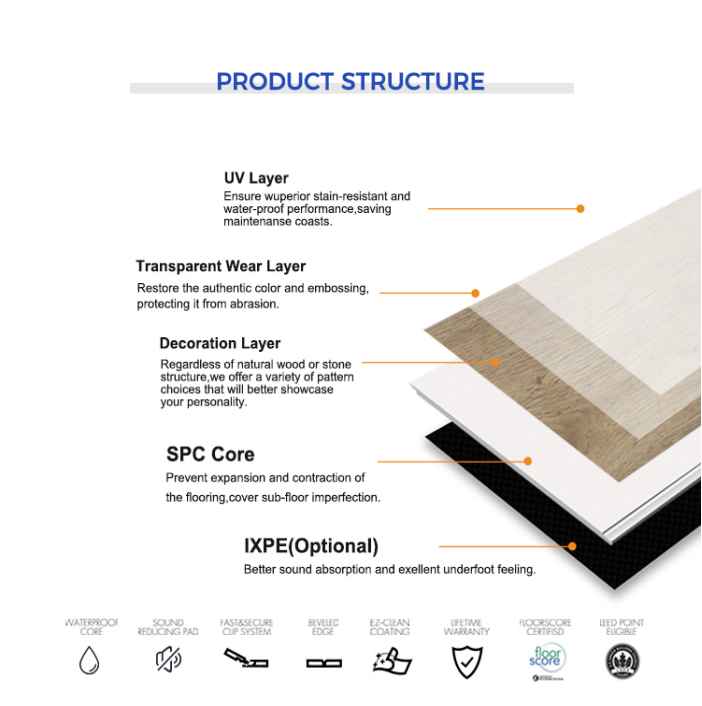

Product Structure

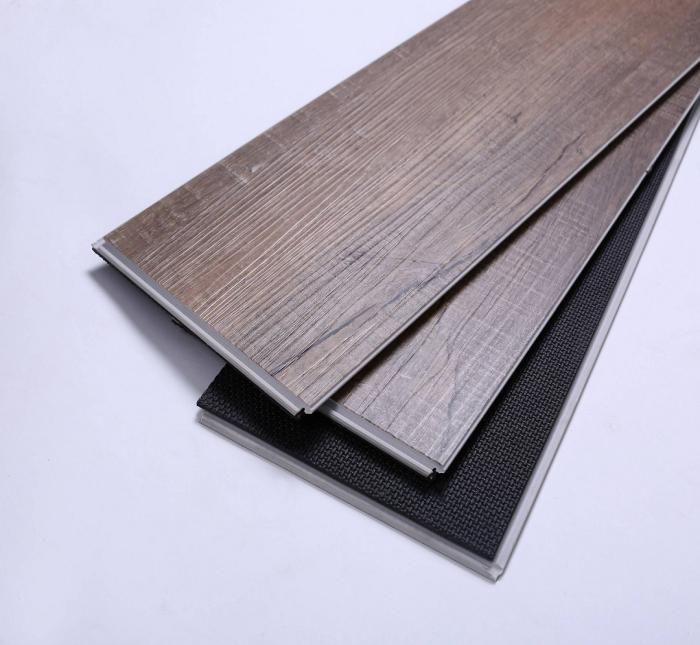

| Name | Vinyl flooring (SPC flooring,click SPC flooring) |

| Color | Based on 3C lap dip series number or as your samples |

| Board Thickness | 3.5mm,4.0mm,4.5mm,5.0mm,5.5mm,6.0mm |

| Wearing Layer Thickness | 0.3mm,0.5mm as regular |

| Surface Texture | Deep Grain,Wood Grain,Marble Grain,Stone,Carpet |

| Finish | UV-Coating |

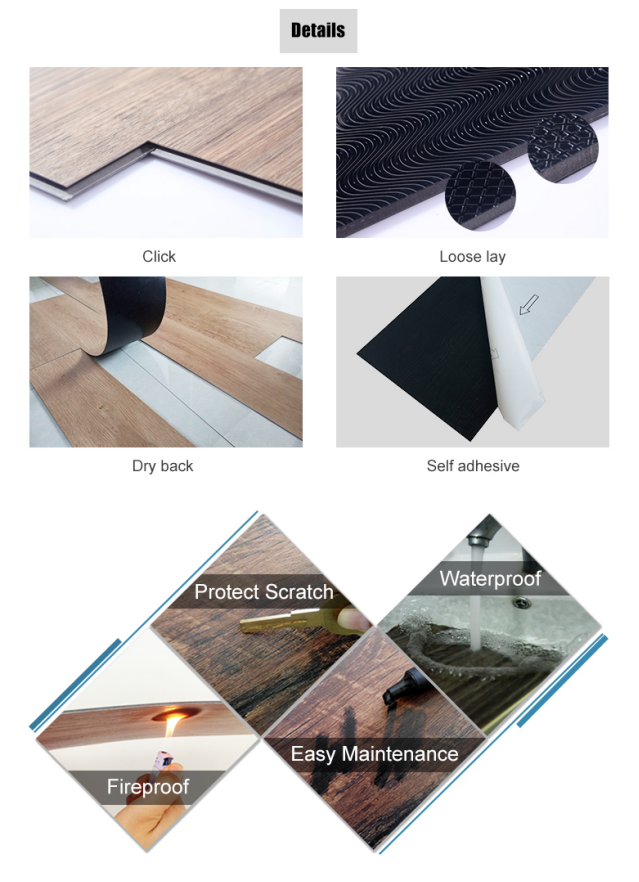

| Installation | Click system(Unilin,Valinge),Loose lay,Dray Back/Glue Down |

| Delivery Time | 15-25 days |

| Size | Inch or MM |

| 6''*48''(150mm*1220mm) | |

| 7''*48''(182mm*1220mm) | |

| 9''*48''(230mm*1220mm) | |

| 9''*60''(230mm*1525mm) | |

| Backing Foam | IXPE(1.0mm,1.5mm,2.0mm) EVA(1.0mm,1.5mm) |

| Density | 2kg/m3 |

| Surface | Wood Embossed,Deep Wood Embossed,Hand scraped,Etc |

| Usages | Bedroom,Kitchen,Basements,Home,School,Hospital,Mall,Commercial to use. |

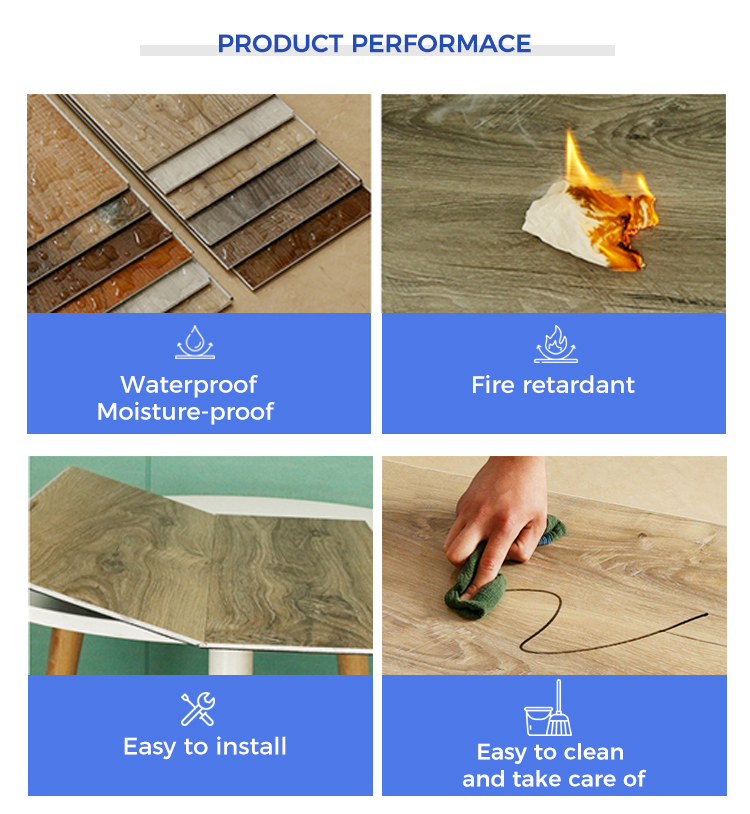

| Features | Waterproof,Wear resistant,Anti-slip,Moisture Proof,Fireproof,durable, anti-scratch, anti-bacterial. |

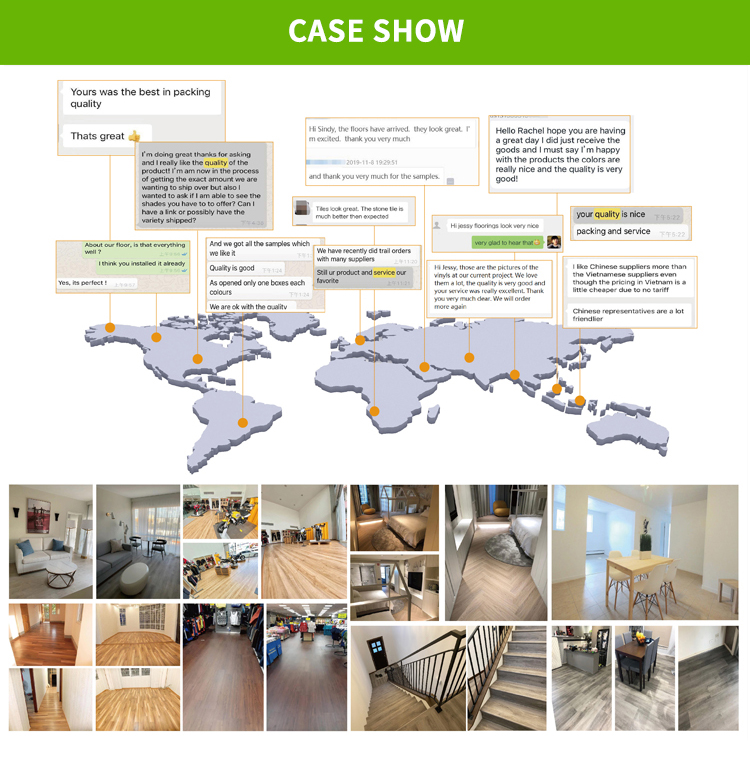

| Market | Export to American,Canadian,European Market,Part Asia,Africa Countries.Australia Market |

| Warranty | 10 years for commercial and 25 years for residential |

Supply Ability 4200000 Square Meter/Square Meters per Month

Lead time:

| Quantity (square meters) | 1 - 1000 | 1001 - 2000 | 2001 - 5000 | > 5000 |

| Lead time (days) | 10 | 20 | 30 | To be negotiated |

Packaging Details: carton+pallet

Port:Qingdao

Best Services

• Try our best to meet and exceed customer's expectation -- Strictly quality control, on-time delivery and prompt responsiveness to customers' requirements.

• Fellow up and feed back tightly during production process.

• Provide real pictures of loading container.

• Provide free samples for trial sale.

• Customized designs, colors, sizes and logos are welcome.

• Price term and payment are negotiable.

Hot Sale Color

Usage Scenarios

Custom Service

Case Show

Detail

Factory View

Certification

Exhibition

FAQ

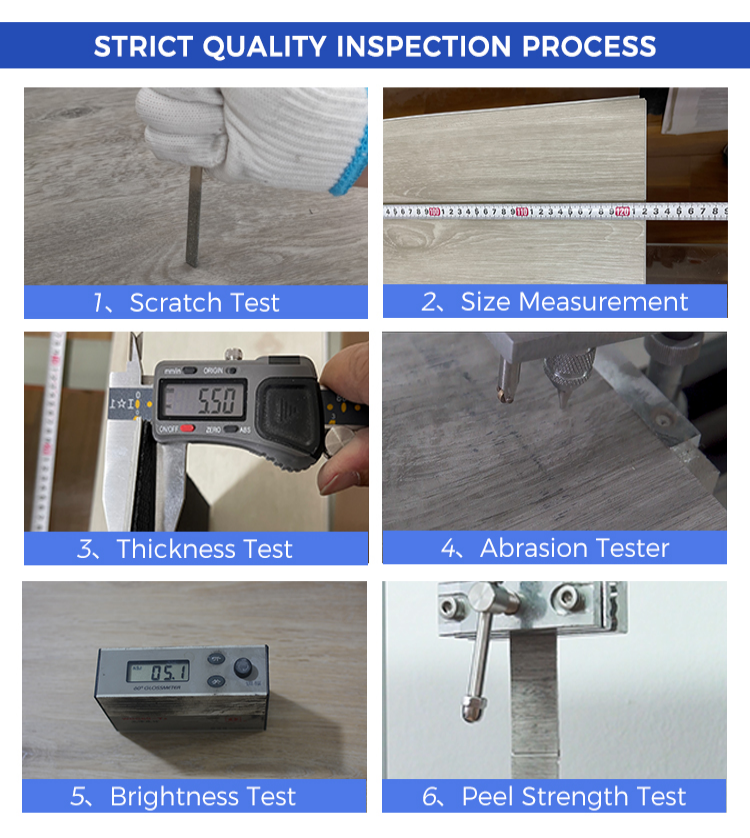

1.How do you guarantee the quality of your PVC vinyl flooring?

Each step is strictly controlled by the QC team to make sure all our products turn out great.

Our products have a limited warranty as long as 7~15 years.

2.How about the delivery time ?

Lead time since receipt of 30% T/T deposit payment : 30 days . (Samples will be prepared within 5 days.)

3.Do you offer other products besides PVC vinyl flooring?

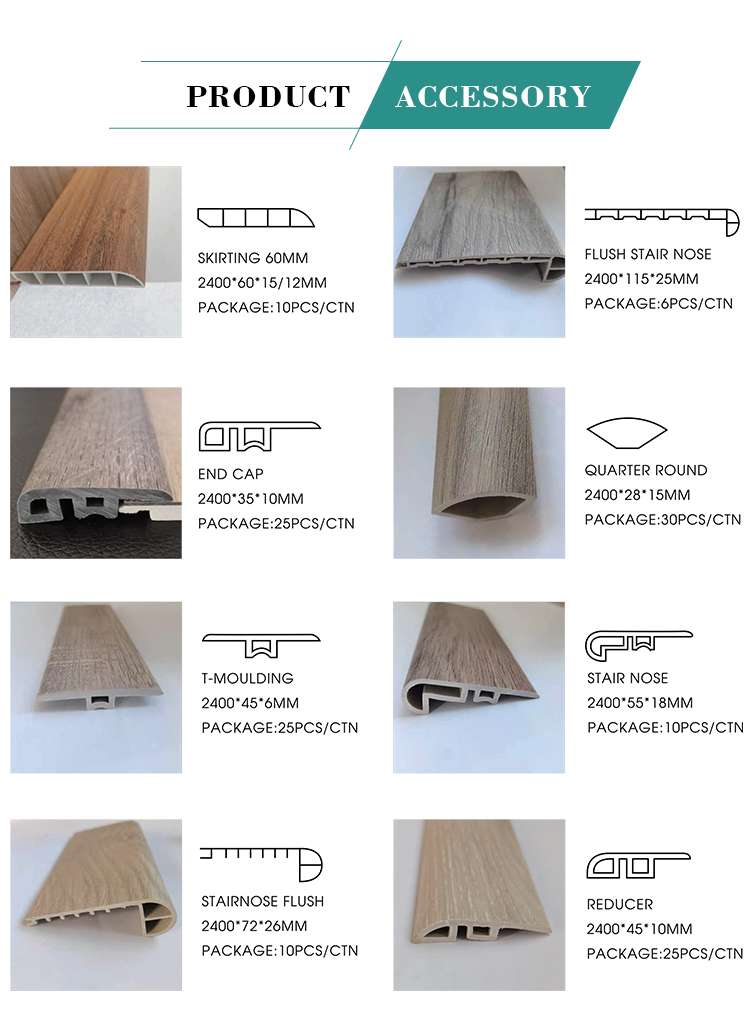

Yes. Besides PVC vinyl flooring we also provide as T-molding, skirting , Click system vinyl flooring, WPC vinyl flooring AND so on interior decoration material .

4.Do you charge for the samples ?

According to our company policy ,We provide free samples ,But the freight charges need customers pay.

5.Can you produce according to customers' design ?

Sure,We are professional manufacturer ,OEM AND ODM are both welcome .